Sugar Drives

Cyclo Transmission Ltd. conducted a study in several sugar plants across India for crystalliser Drives based on speed and capacity of crystalliser, the Power consumption, size, maintenance frequency, and construction of the drives. It was observed that the power consumption of this application was two to three times the actual requirement at the crystalliser shaft. The existing drive unit was highly inefficient due to the double worm reduction arrangement. The maintenance costs of these units were also higher due to open gearing.

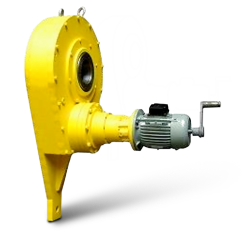

As a solution to the above problems, Cyclo Transmissions Ltd. introduced planetary gearboxes for crystalliser in Sugar industry. Cyclo planetary gearboxes have helped in reducing the power consumption to almost one third compared to conventional double-worm reduction drives. The drives are fully enclosed to provide sealing against dust and other foreign particles, and hence longer gearbox life. All gears and bearings are splash lubricated which also facilitates heat dissipation. The gearbox has a handle for manual operation in case of power failure.

CYCLO Crystalliser Keyed Series speed reducers are available in five models with a wide variety of reduction ratios and various choices of mounting options (Frame sizes). These units mount available in hollow shaft with torque arm.

This drive builds with multi stages planetary (input side) and one stage spur (output side) hence offer the advantages of compact design, smaller size, required reduction ratios and higher efficiency than conventional Crystallizer drives.

Planetary gears, Spur gears and shafts are of hardened alloy steel. Gears are manufactured to ensure smooth, quiet running with maximum life and efficiency. Ball bearings are used to carry adequate radial and thrust loads and support the shafts

Drive Rating

- Torque Capacity : 1,000,000 NM.

- Reduction Ratio : 30 onwards

- Torque rating : 95000 NM.

- Power Rating : 037kw to 75kw